Lucas Trihey 2/3/2020

We take a range of trucks to the Bash each year. This includes B-Doubles, semi-trailers, heavy-rigid trucks, single and bogie drive curtain-side trucks, a crane truck, smaller hire trucks and pantechs. Some have tailgate lifters or tilt-trays. Here’s what we’ve learned.

Every truck gets a bit of ruggedizing. Most trucks used in the city or on sealed roads have vulnerable parts that can be damaged by the flying rocks on the roads of Western Queensland. Our own trucks are permanently toughened up and even hired trucks get temporary rubber stone guards fitted and sensitive parts underneath are protected.

If we won’t meet up with the truck until part way through the journey we take extra rubber flap material and cable ties so we can fit on the road somewhere.

Tyres

On gravel roads we run truck tyres 50% lower than highway pressures. 100psi on the highway becomes 50psi on rough gravel roads. We find this reduces tyre damage and cuts down on vibration damage to the truck body and cab. See the tyre post for more info.

We love tyre pressure and temp sensors and are adding these to more of our trucks. Saving a single tyre caused by a slow leak will pay for a good tyre sensor system.

Underbody protection

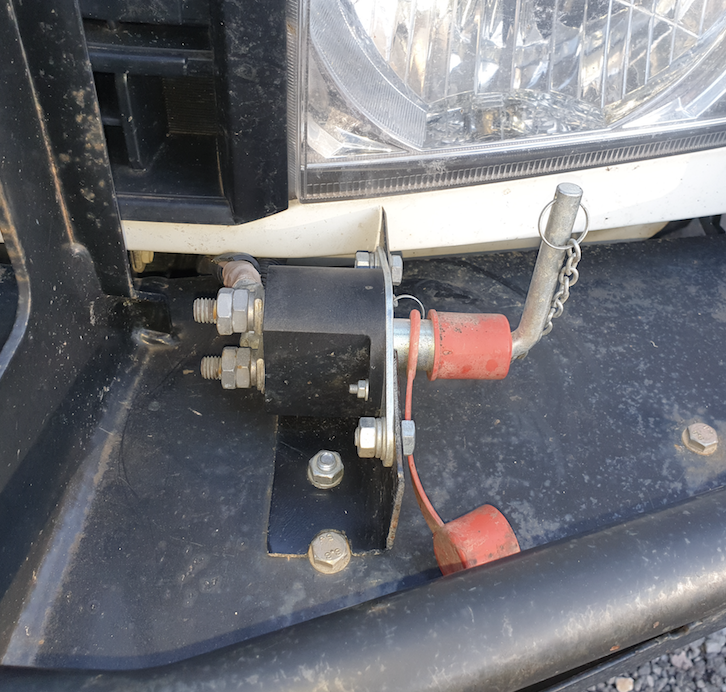

We fit rubber matting across the full width of the trucks, just behind the steer tyres. On semis we also fit a second mat behind the prime mover drive axles. This rubber minimises rocks and stones richoceting around under the trucks that can damage vulnerable parts like brake hoses, sensors, cooling fins, hydraulic hoses, fittings and handles.

Sensitive parts like cooling fins, the sensors on transmissions and diffs and the controllers for tail-gate lifters or tilt-trays often get secondary protection of their own – usually more rubber, corflute or similar.

Air lines

There’s A LOT of vibration on outback roads and any airline that’s near a steel edge or anything sharp can wear through. We fit a split hose over these wherever they pass through a hole or rub against a bracket or part of the underbody. Nylon air lines are thinner and more brittle and get special protection – a split garden hose works a treat.

Fuel lines

Vibration and flying rocks will damage any hose not well protected. Make sure fuel lines are routed behind steel cross members or underbody steelwork where possible. Protect fuel lines with an extra layer of split hose.

The under-tank drain tap is very vulnerable to rock assault and breakage so make sure these have a stout rubber flap over them for protection. Or cap off the outlet for the outback trip.

Hydraulic lines

The hydraulic hoses and any steel pipework for Hiab cranes, tailgate lifters or tilt-tray mechanisms need protection using rubber flaps, spiral wrap protection (available from hydraulic suppliers) or by routing away from damage-prone areas. Take special care with the taps and controllers down the back of the truck, we often put an extra temporary cover over these for the long trip out to Birdsville.

Crane parts and bearing surfaces

Our Palfinger crane has large areas of exposed steel rams and bearing surfaces for the slew movements. It’s impossible to keep these free of bulldust and sand on the drive out west. On arrival we clean and grease these parts using compressed air and a grease gun.

Finned air and oil coolers

Modern trucks have a plethora of finned coolers that hang low and are vulnerable to rock damage. These can be for transmissions, aircon and all sorts of other extras. These fins need their own rubber flaps for protection but be careful not to impede airflow too much or you’ll see overheating. A good solution for these is often to fit a big flap 500mm in front of the fins that will stop the rocks but still allow air to swirl around it when mobile.

Electronic Sensors

Sensor alerts are the bane of late model trucks on outback roads. We’ve been stopped a few times when the transmission sensors on hired trucks get a splatter of mud on a creek crossing that causes the truck to go into limp mode – this can make for a very slow trip. Try and find out where the sensors are and do what you can to protect them from muddy water and if that fails slow right down for creek crossings to avoid water spray getting up over transmissions and gear boxes.

12 Volt power supply in the cab

We often find ourselves in a 24 volt truck so we sometimes need to fit a 12V power supply for a fridge or similar in the cab. We usually run double insulated heavy twin wiring from the battery into the cab (via the cab-tilt hinges) for this purpose. Auto electricians call this double insulated wiring “gas wiring” because it’s the same as what they use for power to gas appliances. Allow a couple of extra hours to fit this or get an auto-electrician to do it.

AdBlue

When hiring a truck make sure to ask if it requires AdBlue. This fuel additive is needed by lots of modern trucks and it can be hard to find in the outback. Phone ahead to ask or if in doubt look into getting your own supply to have on board. Most of these trucks will change to limp mode if you run out of AdBlue and it’s a long way from Windorah to Birdsville at 55km/h.

Truck and cab vibration on corrugated roads

We’ve found that the secret to reducing potentially damaging vibration on badly corrugated roads is to have lower tyre pressures and to experiment with speed to try and find the sweet spot that shakes the least. Really bad vibration can break cab mounts or crack windscreens. It can loosen and damage radiators and anything else bolted to the truck or engine. Trucks will break if shaken badly enough for long enough, treat them kindly. On rare occasions there is no sweet spot on corrugations and the only solution is to drop back to 50km/h and enjoy the scenery. Allow extra time in your schedule for gravel roads.

Driver fatigue management

Our drivers follow strict fatigue management driving and rest breaks in the outback. We always allow extra time in our schedules for flat tyres, minor breakdowns, regular maintenance and air pressure adjustments.

It’s possible to drive from Medlow Bath in the Blue Mountains to Birdsville and meet log-book requirements in just over two days – but we always allow three days for the unexpected and to make sure drivers arrive alert and safe.

Although drivers of smaller trucks and utes don’t need to follow government log book times we get everyone to use the same guidelines anyway – it’s a great way to avoid driver fatigue.

Below is a link to the Queensland professional driver standard hours which are the same for all states. Most infrequent drivers will have more rests and drive fewer hours than this on a given day – but you want to make sure you or your drivers definitely do NOT EXCEED these driving hours.

Roo, emu and cattle collisions

A big enough roo or cow can cause a lot of damage to a truck so we stick to the same rules for all our drivers – get off the road before sunset.

On the rare occasion that a delay requires a bit of night driving we put the truck with the best bullbar and best driving lights at the front of the convoy and we keep good radio communications going to warn of random animals on the side of the road. But even then there’s a high risk of doing very expensive damage. We avoid it where possible.

Big trucks on narrow roads

Outback Queensland has long stretches of single-lane bitumen with narrow and rough gravel shoulders.

We advise our truck drivers to stay on the sealed top and let the smaller vehicles pull off. It can be quite risky to take a big truck onto the sloping shoulder and the risk of tipping over is high. But some car drivers and those towing caravans don’t understand and will only get partially off in the expectation that the truck will do the same. The larger truck tends to rule in this situation although trucks drivers should always travel slowly enough to take evasive action if needed (or to give the car drivers more time to realise that it’s better for everyone if they get right off the road and allow the truck to stay on the narrow sealed section).

If another truck comes the other way there’s usually a short discussion over the CB and the smaller truck, or the one with the best shoulder on their side will usually offer to get off the sealed surface.

Wet and slippery roads

Trucks are big and heavy and can be difficult to get out of a bog. Be really wary about where you take them. Send a 4WD or smaller vehicle ahead if in doubt before pulling off to camp if it’s been wet or recently flooded. Know how to use diff and cross-locks if fitted and what their limitations are.

Creek crossings and flooded areas

Trucks with bigger wheels are often the first vehicles allowed to cross deep, flooded crossings once the waters start to recede. Watch what more experienced outback truck drivers do and if in doubt wait and play it safe. Beware of creek crossings where there’s a chance of a washout in the flooded road surface. If in doubt walk it first (still water only).

Enforced stop overs

Sometimes the only option is to camp in a town or beside a flooded crossing and wait for it to go down. If entering areas with a prospect of flooding make sure to carry extra fuel for long detours. And keep extra fuel on hand for generators that provide power for cool rooms or fridge units.